How To Repair Boot Stitching

Frequently at Gear Patrol, we implore readers to invest in quality boots. We wax poetic about how a great pair will age: how it will develop a unique patina, how it volition form to the wearer's foot, how it can be resoled countless times. We talk most it similar it'southward a serious investment, not as a rhetorical do, because it actually is. Almost quality boots cost hundreds of dollars and are designed to last for years.

When many brands or retailers depict expensive boots, they oft rely on manufacturing processes as marketing terms. This is Goodyear welted, therefore, it is a quality product. Though structure processes undeniably have an issue on the quality of a boot, one method is not necessarily ameliorate than another. They accept different purposes and features, resulting in boots appropriate for unlike situations. A problem arises when we stop equating a manufacturing term with its process and start equating it a value: good or bad. When this happens, a term can exist wielded as a marketing strength, confusing process with virtue.

And so to clear some of the haze enveloping rhetoric and process, nosotros decided to explore a few typical types of boot construction. Often, information technology's difficult to flick how a boot is actually put together, where the stitches get and what you're actually standing on. Then we sourced prime examples of each type — Cemented, Blake/McKay, True Moccasin, Goodyear Welt and Stitchdown — from some of the top brands in the industry and asked Brooklyn article of furniture maker Asa Pingree to cutting them in half. (Swipe through to the stop of each slider beneath to watch him at work.)

Looking at their cross sections, we're able to clearly see what components go into a pair of boots and how they are all connected. We tin can come across why some construction styles take more time than others (and therefore cost more) and how some styles utilize more materials. Near importantly, in understanding how the upper, insole, midsole and outsole relate to each other, nosotros tin can begin to see the values inherent in each construction method and how those might be relevant to our own lives.

Terms to Know

Insole: The interior surface of the boot that comes in contact with the sole of your human foot.

Last: The wood or plastic form used to create the shape of a kick.

Midsole: A structural layer of the boot that sits betwixt the outsole and the insole.

Outsole: Sometimes just called the sole, this is the bottom surface of the boot that comes in contact with the footing.

Upper: The combination of parts of the boot's elevation, including quarters (which wrap around the heel), vamp, tongue and saddle.

Vamp: A function of the upper that covers the instep of the foot and can extend over the toe in certain styles.

Welt: A narrow strip of leather on the exterior of the shoes that secures the midsole to the upper.

Cemented Construction

Blundstone Original 500 Boots: Cement construction is the fastest, most affordable method to attach an upper to a sole. Australian brand Blundstone makes what is regarded by many every bit one of the industry-leading cement construction boots. For its iconic Original 500 boot, the brand uses adhesive to gum the weather condition-proof oiled-leather upper to the slip-resistant polyurethane outsole. No welting is used in this style structure, so information technology's not like shooting fish in a barrel to re-sole the boots. But considering they're relatively easy to produce, they tend to be more than affordable than boots made with other methods.

The cemented structure does allow Blundstone to integrate a number of condolement-based materials to the midsole. The kick features an SPS Max Comfort system made up of Poron XRD microcellular impact technology. This open prison cell, breathable foam textile — positioned directly under the heel — combined with a cushioned midsole provides a high level of comfort from the first wear. A removable foam insole offers another small layer of padding. Which means you don't have to spend weeks or months breaking them in.

Buy Now: $180

Other Examples

2976 Smooth Boot by Dr. Martens $145

Refined Slim Fit Chelsea Boot past Hunter $155

Andreas Boot by Roa $490

Blake/McKay Structure

Frye Chase Lace Upwards Boots: Blake/McKay construction is and then named because information technology relies on a stitching machine invented in 1856 by Lyman Blake (the patent for this car was after sold to Gordon McKay). The concept is straightforward: the upper is wrapped under the insole, and these two components are secured to the outsole with a single stitch. This produces a sleek shoe that tin can exist re-soled, but is lighter and easier to produce than Goodyear-welted alternatives.

A variation of this manner, chosen the Blake/Rapid Structure, is also commonly used. In this style, the upper and insole are Blake-stitched to a leather midsole, which is then rapid-stitched to the outsole. As opposed to traditional Blake/McKay structure, this way of construction is more than weather-proof, less-flexible and more rugged (the exterior rapid stitching gives the boot a more than substantial silhouette).

Frye's Chase Lace Up boot features an Italian buffalo leather upper with a leather lining and leather insole. A foam midsole, which will eventually mold to the wearer's foot, sits between the insole and outsole. This boot utilizes traditional Blake construction: a single stitch attaches the insole, foam midsole and outsole. The stitched welt on the exterior of the kicking is aesthetic, fastened to a strip of leather that forms a perimeter around the foam midsole. This makes for a flexible, comfy boot out of the box.

Buy At present: $528

Other Examples

Chaves Kicking past Oliver Sweeny $353

Shelby Boot past To Kicking New York $398

Jort Boot past Accommodate Supply $449

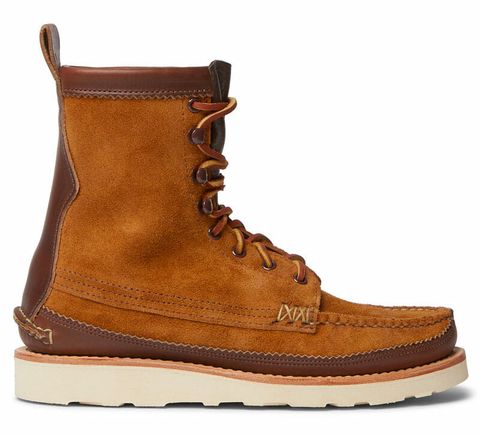

Truthful Moccasin Construction

Rancourt Harrison Boots: Truthful Moccasin structure is an iteration of traditional ethnic footwear styles. A continuous piece of leather (the vamp) is wrapped around the sides and bottom of the kicking, forming a shape akin to a hammock. This one-piece structure provides comfort unrivaled by other styles of construction. The vamp is then sewn to the remainder of the upper and toe box and, in mod iterations, Blake-stitched to a midsole to which a more than substantial outsole is attached.

The standard-bearer for this type of construction is Maine-based bootmaker Rancourt and Co. The brand's Harrison Boot features an upper fabricated from heavyweight Flit Kudu suede. The way includes a hand-sewn toe box, machine-stitched mudguard (reinforcing the vamp) and a leather lining. A padded insole sits below the heel and the vamp is Blake-stitched to a leather midsole. Attached to this, a Vibram 148 Kletterlift sole with a foam wedge midsole provides increased traction and comfort.

Buy Now: $285

Other Examples

7 Eyelet Field Boot by Maine Mountain Moccasin $399

America Bison 5.v "PH" by Russell Moccasin Co. $460

Maine Guide Boots past Yuketen $630

Goodyear Welt Construction

Wolverine Evans 1000 Mile Boots: In 1869, Charles Goodyear, Jr. invented a footwear-stitching machine that could produce durable shoes and boots that were easy to re-sole. The eponymously named Goodyear Welt Construction has become something of a gold standard in the kick earth. For this mode of construction, the bottom of the insole is prepared with a rib that runs forth the contour of the foot (some brands cut and carve the insole while others attach a rib fabricated from boosted material). The automobile then secures the insole rib and upper to a sparse piece of leather encircling the outer forepart of the kicking (the welt). An additional rapid stitch secures the welt and midsole to the outsole.

The Evans thousand Mile Boot, fabricated by Michigan-based make Wolverine, is a classic case of a Goodyear-welted boot. The style features a Horween-leather upper, leather midsole and leather outsole, strengthened with a Vibram safety front and heel. As with many Goodyear-welted boots, a cork filling sits betwixt the insole and midsole which volition mold to the wearer's foot over time. Considering of the additional welting and stitching, the kick is less flexible out of the box, but more durable and easier to repair after years of wear.

Buy Now: $400

Other Examples

8085 Atomic number 26 Ranger Boots past Ruby-red Wing Heritage $320

Trench Kicking by Oak Street Bootmakers $426

Combat Boots past John Lofgren $820

Stitchdown Construction

Viberg Service Boots: Stitchdown construction, as the proper name implies, features an upper stitched down to the midsole. One of the oldest construction methods notwithstanding widely used, it was developed in Dutch South Africa. Canadian bootmaker Viberg is a strong proponent of this style of construction, showcased in the brand'due south flagship Service Boot.

Designed in 1931 by Edwin Viberg, the style features a leather upper which is flanged outward and stitched to a substantial leather midsole. An additional rapid sew together secures the upper and midsole to a Dainite rubber outsole. On the interior, the boot's leather lining is sandwiched between the hefty leather insole and midsole. Unlike other boots that use cork filler, Viberg's boots are substantially stacked leather. This makes for a more substantial kick — it's heavier and stiffer from the start wear and it will accept longer to mold to the wearer's foot. Likewise, a thicker heel-counter noticeably cups the wearer's foot and provides more stability than other brands. When the boot does break in, the fit and longevity will be unmatched by other construction styles.

Buy Now: $710

Other Examples

Danner Low-cal by Danner $380

Cykel Boot past White'south Boots $410

Jobmaster by Wesco $595

Blundstone, Frye, Rancourt and Co., Wolverine and Viberg provided product for testing.

This content is created and maintained by a third party, and imported onto this page to aid users provide their email addresses. You may be able to find more information about this and similar content at piano.io

Source: https://www.gearpatrol.com/style/shoes-boots/a510358/boot-construction-explained/

Posted by: welchercland1951.blogspot.com

0 Response to "How To Repair Boot Stitching"

Post a Comment